Gas Spring

Product Introduction

Nitrogen spring is a new type of elastic component that uses high-pressure nitrogen as the working medium. It has the advantages of small size, large elasticity, long stroke, stable operation, precise manufacturing, long service life, gentle elastic curve and no need for pretension.

Mold nitrogen spring can also be designed as a nitrogen spring system, as part of the mold to participate in the work, can be very convenient in the system to achieve constant pressure and delay action, is a kind of flexible performance of a new generation of ideal elastic parts.

Scope of application

With the rapid development of the mold industry, nitrogen spring has gradually replaced the traditional mechanical spring and has been widely used. At present, it is commonly used in metal stamping forming molds, metal blanking flanging molds, high-precision electronic plastic molds, etc.

Nitrogen spring parameters

Die dedicated nitrogen spring basic technical parameters:

Initial projectile pressure F:Refers to the spring pressure of the initial state when the inflation pressure of the series of nitrogen springs is 15MPa at 20 ℃. When there is no special requirement, the nominal bomb pressure is made according to the initial bomb pressure. Initial elastic pressure range: 45~20000KG

Trip S:Working stroke of nitrogen spring, stroke range: 7~1500mm. (For safety of use, keep a safety stroke of> 5mm or 10% S in the design)

Working environment:-20 ℃ ~ 80 ℃

Working life:Working life: when the stroke is less than or equal to 50mm, the service life is 1.5 million times. When the stroke is> 50mm, the total stroke of the piston rod is 100000 meters. Working life = 100000 m ÷ (actual stroke × 2)

Series Products

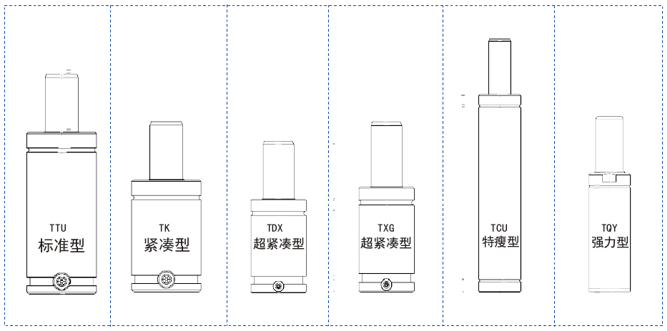

There are six series of nitrogen springs for molds: TTU standard type, TK compact type, TDX ultra compact type, TXG ultra compact type, TCU ultra thin type and TQY strong type. The products corresponding to the different series of major brands are completely universal and interchangeable on the mold.